Understanding In-Mold Decorations: Techniques, Fads, and Best Practices for Optimum Results

In the world of manufacturing, the art of in-mold designs stands as a critical facet of product style and manufacturing. As markets consistently seek ingenious ways to improve aesthetic appeal and performance, understanding the complexities of in-mold decors has become an essential ability. From picking the appropriate materials to integrating cutting-edge style fads, the trip in the direction of accomplishing ideal lead to this domain name is diverse. By diving right into the strategies, patterns, and finest techniques that underpin effective in-mold decoration procedures, businesses can unlock a world of opportunities that not just boost the aesthetic allure of their products however additionally simplify production efficiency and reinforce customer interaction.

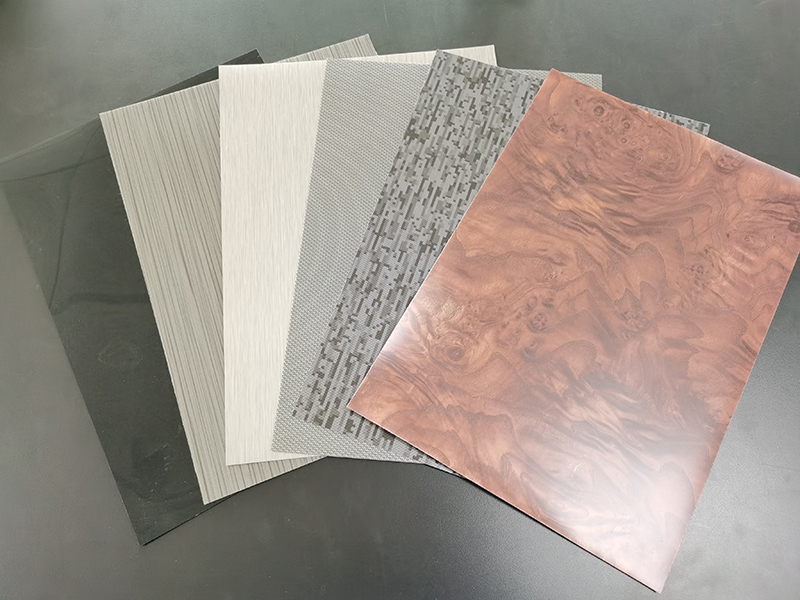

Product Option

Product choice is a crucial facet of grasping in-mold decors, as it directly influences the high quality and durability of the last item. When selecting products for in-mold decorations, it is vital to think about factors such as compatibility with the molding procedure, the wanted aesthetic end result, and the environmental conditions the item will deal with.

Moreover, the chosen product ought to have excellent adhesion residential or commercial properties to make certain that the decoration sticks strongly to the substrate during the molding procedure. Attachment between the material and the decor is vital for preventing delamination and guaranteeing durable aesthetic appeal. Furthermore, products with high warmth resistance are preferred for in-mold decorations, particularly for items that will certainly be revealed to raised temperatures during their lifecycle. By thoroughly choosing the ideal product for in-mold decorations, manufacturers can enhance the overall quality and sturdiness of their items, meeting the assumptions of both end-users and customers.

Layout Innovation

An essential factor in progressing the area of in-mold designs is the constant exploration and implementation of layout technology strategies. Style development plays an important role in enhancing the visual charm, functionality, and overall top quality of products manufactured making use of in-mold design processes. By incorporating innovative style elements, suppliers can separate their products in the market, bring in consumers, and remain in advance of competitors.

Among the essential aspects of layout development in in-mold decorations is the combination of elaborate patterns, appearances, and graphics that were formerly testing to accomplish with traditional decor techniques. Advanced modern technologies such as 3D printing and digital layout tools make it possible for designers to develop complicated and detailed styles that can be seamlessly moved onto shaped parts. In addition, making use of vivid colors, metal coatings, and special results like gloss or matte textures can additionally elevate the visual allure of in-mold embellished items.

Furthermore, style technology expands beyond aesthetics to incorporate functional improvements such as ergonomic forms, integrated functions, and personalized elements that accommodate details user requirements. By accepting layout development, makers can open new possibilities for customization, creative thinking, and item distinction in the competitive landscape of in-mold decorations.

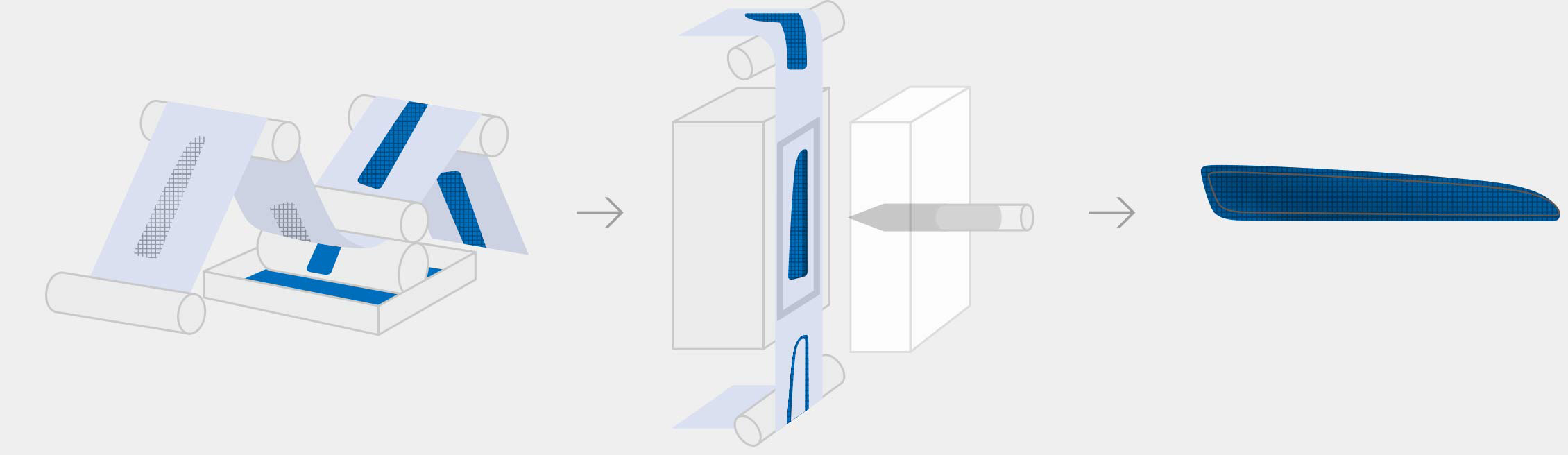

Production Efficiency

Effective production procedures are crucial for equating the ingenious designs created in the area of in-mold decorations right into top notch completed products that fulfill market demands and consumer assumptions. In the realm of in-mold decorations, manufacturing effectiveness encompasses numerous essential aspects that add to the overall success of the production process.

Automation not only accelerates the production process however likewise improves accuracy and repeatability, leading to a more uniform and top notch end item. Overall, a holistic approach to production efficiency is critical in taking full advantage of the capacity of in-mold design methods and accomplishing ideal results in the competitive market landscape.

Quality Control Measures

What are the key strategies for guaranteeing stringent quality assurance measures in the world of in-mold decors? Quality assurance steps are critical in in-mold decoration procedures to make certain the manufacturing of top quality and flawless ended up items. One important technique is the implementation of strenuous assessment procedures at every stage of the manufacturing process. This involves performing complete visual inspections, dimensional checks, and shade consistency assessments to identify any type of incongruities or issues at an early stage.

Utilizing sophisticated technologies such as computerized inspection systems can likewise boost the quality control procedure by giving accurate and trusted information for analysis. These systems can find imperfections that may be missed out on by hand-operated evaluations, consequently boosting overall product high quality and uniformity.

Regular training and advancement programs for staff members entailed in the in-mold decoration process can likewise add to maintaining premium requirements. By enlightening staff on best methods, high quality assumptions, and the importance of attention to detail, business can promote a society of top quality awareness throughout the company.

Consumer Appeal

To enhance the marketability of in-mold decoration products, catering and comprehending to consumer preferences play an important function in identifying their charm and success. Customer charm in in-mold designs is influenced by different elements, including style looks, shade selections, longevity, and overall functionality. Customers are progressively looking for personalized and one-of-a-kind items that mirror their originality and design. Providing customization options such as tailored styles, color variants, and textural aspects can considerably enhance the allure of in-mold design items.

Final Thought

In-mold decorations provide a reliable and functional way to enhance product aesthetic appeals. By meticulously useful source picking products, embracing innovative designs, optimizing production processes, executing high quality control procedures, and focusing on consumer charm, makers can accomplish ideal results. It is important for business to continuously adapt and enhance their techniques to stay competitive in the market. In-Mold Decorations. Mastering in-mold decorations calls for an all natural strategy that thinks about all elements of the manufacturing process to ensure success.

In the world of manufacturing, the art of in-mold decorations stands as a crucial element of product layout and manufacturing. Design technology plays a crucial internet role in boosting the aesthetic appeal, capability, and overall top quality of products made utilizing in-mold decoration procedures.One of the essential facets of style technology in in-mold designs is the integration of complex patterns, textures, and graphics that were formerly testing to accomplish with traditional design approaches.Effective manufacturing processes are crucial for translating the cutting-edge designs established in the area of in-mold designs right into top quality ended up products that satisfy market needs and customer expectations. Using customization choices such as tailored designs, color variants, and textural components can considerably improve the allure of in-mold decoration products.